|

This page is provided for historic reference only. Please use the following URL's :-

|

||

| Create

and professionally document layer stackups in an instant.

|

|||

|

Request a Speedflex evaluation View Speedflex video |

Speedstack brochure screen / print(4MB) |

||

| Material libraries for Speedstack are available exclusively for Polarcare customers from Polar's supplier partners listed in the Polar Materials Partner program | |||

| Speedflex for Speedstack | |||

|

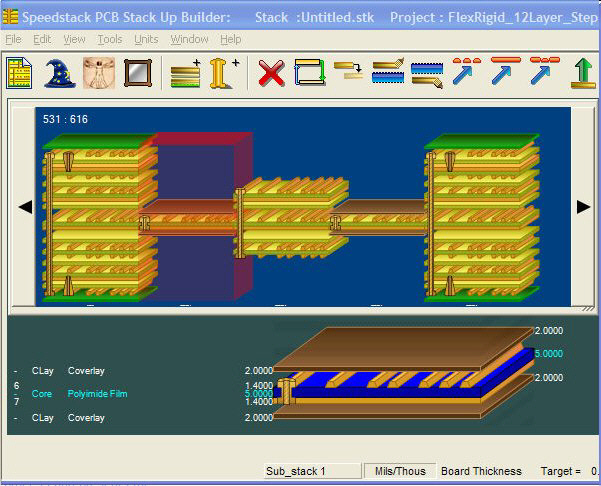

Speedstack with Speedflex Navigator – click to view full graphic Why create stackups with Speedflex? Speedflex allows PCB fabricators and OEM engineers to create and document flex-rigid PCB layer stackups using the Speedstack family of PCB design tools. What will Speedflex do for me? OEM designers PCB fabricators How? Easy graphical stackup display Speedflex 2D mode – click to view full graphic Speedflex 3D mode – click to view full graphic A range of materials including flexible adhesives, bond ply and FlexiCore can be enabled or disabled for each layer, and impedance structures can be added to each sub-stack. Without Speedflex... Flex-rigid PCB manufacture can be expensive in money and time and using the traditional, informal methods of exchanging stackup information is prone to misinterpretation as the stack is passed around the supply chain. Errors in stack documentation can all too easily result in board scrappage and remanufacture. Interactive Speedflex brings reduced cost and enhanced reporting capability... Speedflex for cost control High quality error-free documentation |

|||